In recent years, high-end Electric bicycles (e-bikes, or electric bicycles) have become extremely popular in the European and American markets. With their dual-purpose outdoor attributes, they can not only meet users' basic commuting needs but also offer a rich riding experience, adapting to the huge demand of the outdoor sports market.

A French electric bicycle manufacturer has joined hands with TSC's subsidiary, LiM Laser, to jointly explore the application scenarios of metal 3D printing technology in this industry, break through the limitations of traditional processes, and create a new generation of high-end electric bicycles that are both competitive in the market and offer a good user experience.

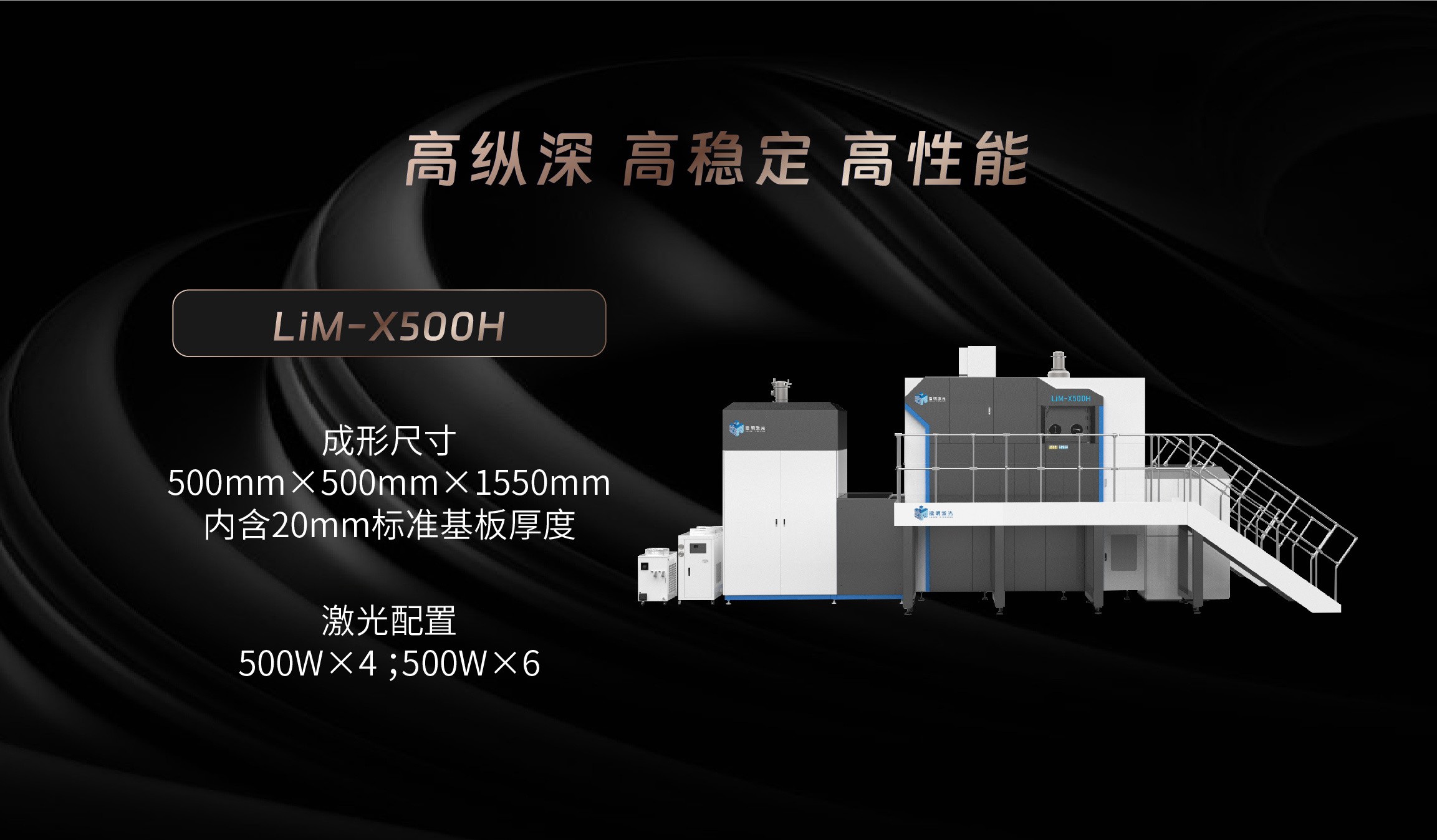

The LiM-X500H equipment of LiM Laser directly and rapidly forms large-sized, irregular-shaped thin-walled structure electric bicycle parts. The size of this workpiece is approximately 554mm×398mm×106mm, formed in one piece, with 100% no welds, avoiding the risks of deformation and fatigue damage caused by residual stress, significantly improving mechanical reliability and enhancing the stability of the finished product. In sharp contrast to the traditional manufacturing methods of "multi-component welding and assembly" or the composite parts that are printed in sections and then assembled and welded together, the performance of the parts has been enhanced in multiple dimensions.

In terms of weight reduction, by leveraging topological optimization algorithms and adjusting the structural design based on actual force analysis, redundant materials in non-load-bearing areas are removed. This ensures structural strength while significantly reducing the overall vehicle weight.

AlSi10Mg material is selected, which has obvious lightweight advantages, high material strength and good corrosion resistance. While further reducing the total weight of the parts, it ensures reliable structural strength. Its excellent corrosion resistance enables it to withstand daily use erosion, thus extending the product's service life.

3D printing leads the development of e-bikes as a new engine

The powerful potential of metal 3D printing technology in lightweight design and complex structure forming has brought a new engine for the development of the high-end electric bicycle industry.

Aerospace-grade process one-piece molding

During the product development stage, rapid prototype iteration is crucial for product updates. The traditional process requires mold opening for manufacturing, which is time-consuming and costly. By adopting metal 3D printing technology, small-batch and multi-version components can be directly formed, significantly shortening the transformation cycle from drawings to physical objects, accelerating the completion of research and development, trial production and product iteration, and helping users respond quickly to market demands. It is particularly suitable for the development of high-end customized vehicle models. During the production and manufacturing stage, large-scale metal 3D printing equipment is adopted to achieve continuous batch production, with high product yield and good consistency, making production more efficient and convenient.

This cooperation, on the one hand, confirms the huge potential of metal 3D printing technology in the manufacturing of high-end electric bicycles; On the other hand, it has also laid a solid foundation for cooperation for LiM Laser to further expand its overseas market.

Facing the global market size of additive manufacturing, we will continue to focus on innovation and R&D as well as the expansion of industry applications. With our strong technological capabilities and rapid response to industry changes, we will provide overseas users with more efficient and flexible solutions.