On October 22nd, the China Aviation Process Equipment Expo opened at the Xi 'an Lingkong Convention and Exhibition Center. TSC & LiM Laser showcased the LiM-X1500H ultra-meter-level metal 3D printing equipment at the event, comprehensively presenting superior solutions and innovative application cases for the integrated manufacturing challenges of large-sized and complex-structured components in the aerospace and other fields, which attracted high attention.

At the opening ceremony, TSC and AVIC Supply Chain held a strategic cooperation signing ceremony. Both sides adhere to the cooperation principle of "friendly collaboration, complementary advantages, mutual benefit and win-win, and common development", give full play to their respective advantages, jointly explore the aerospace market, and promote domestic high-end equipment to go global.

This cooperation deeply integrates the technological advantages of the subsidiary, LiM Laser, with the channel resources of AVIC Supply Chain, and will provide aviation manufacturing enterprises with a comprehensive solution ranging from equipment selection, process development to after-sales service.

The LiM-X1500H, as a representative of ultra-meter-level metal additive manufacturing equipment, shone brightly at the exhibition site. With an ultra-large forming space of 1500mm×1500mm×1650mm, it precisely matches the manufacturing demands of aerospace-grade industries. It can not only achieve the integrated rapid forming of large-sized, over-specification, and complex-structured components, It can also handle the batch manufacturing tasks of medium and large-sized components.

The equipment is standardly equipped with 16 1000W lasers and can be optionally equipped with 24 lasers, with a maximum forming efficiency of up to 1500cm³/h. The innovative double-layer wind field design and the intelligent dynamic bidirectional variable-speed powder spreading system significantly enhance the consistency and stability of large-format multi-laser printing.

The overall structure design is reasonable and the layout is compact. Relying on self-developed patented technology, the overall height of the machine is controlled within 6.5 meters, with strong adaptability and high compatibility with factory buildings. The safety redundancy design and multiple monitoring systems provide comprehensive guarantees for the long-term stable operation of the equipment, meeting the strict requirements for equipment reliability in the aerospace field.

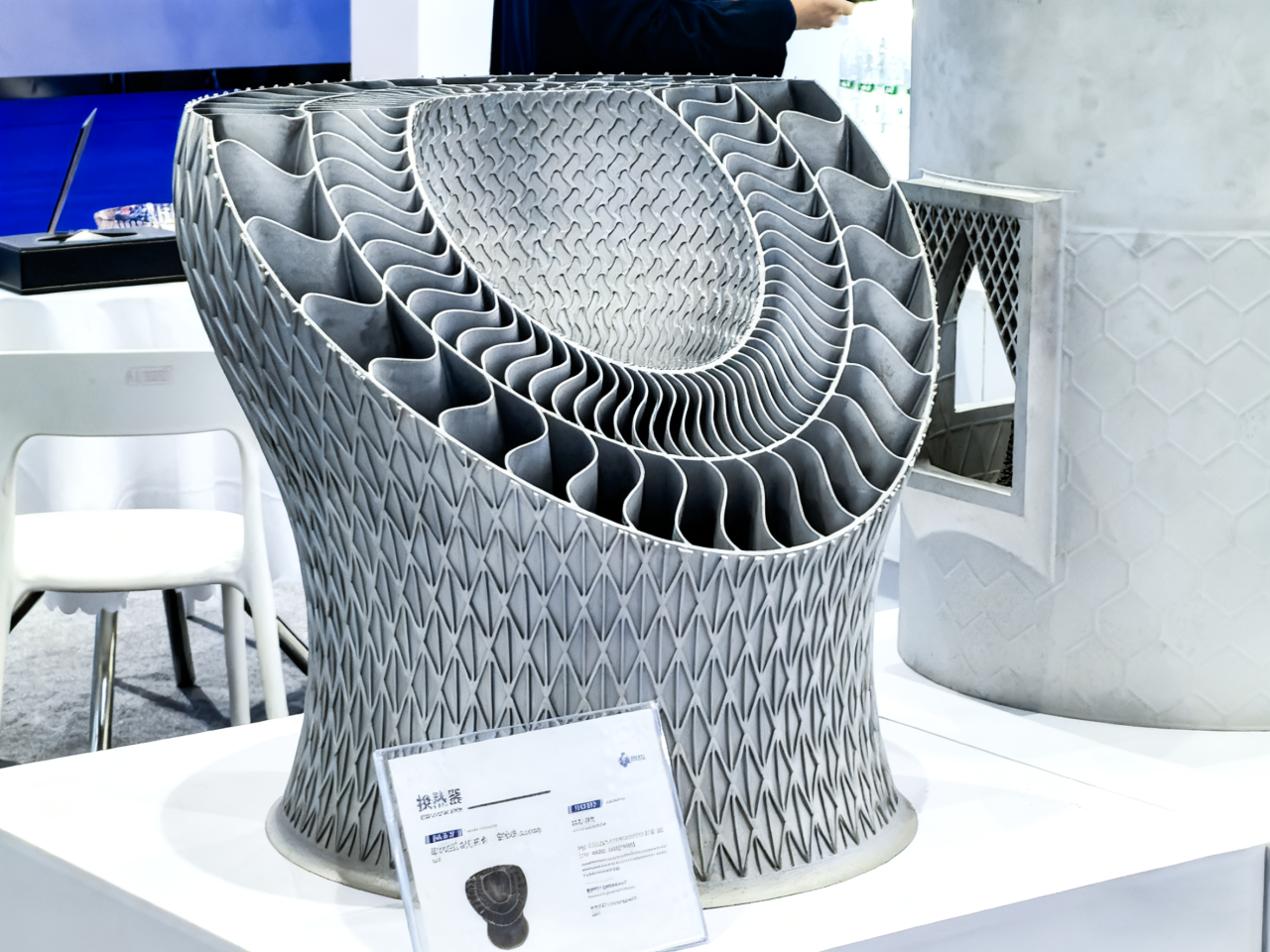

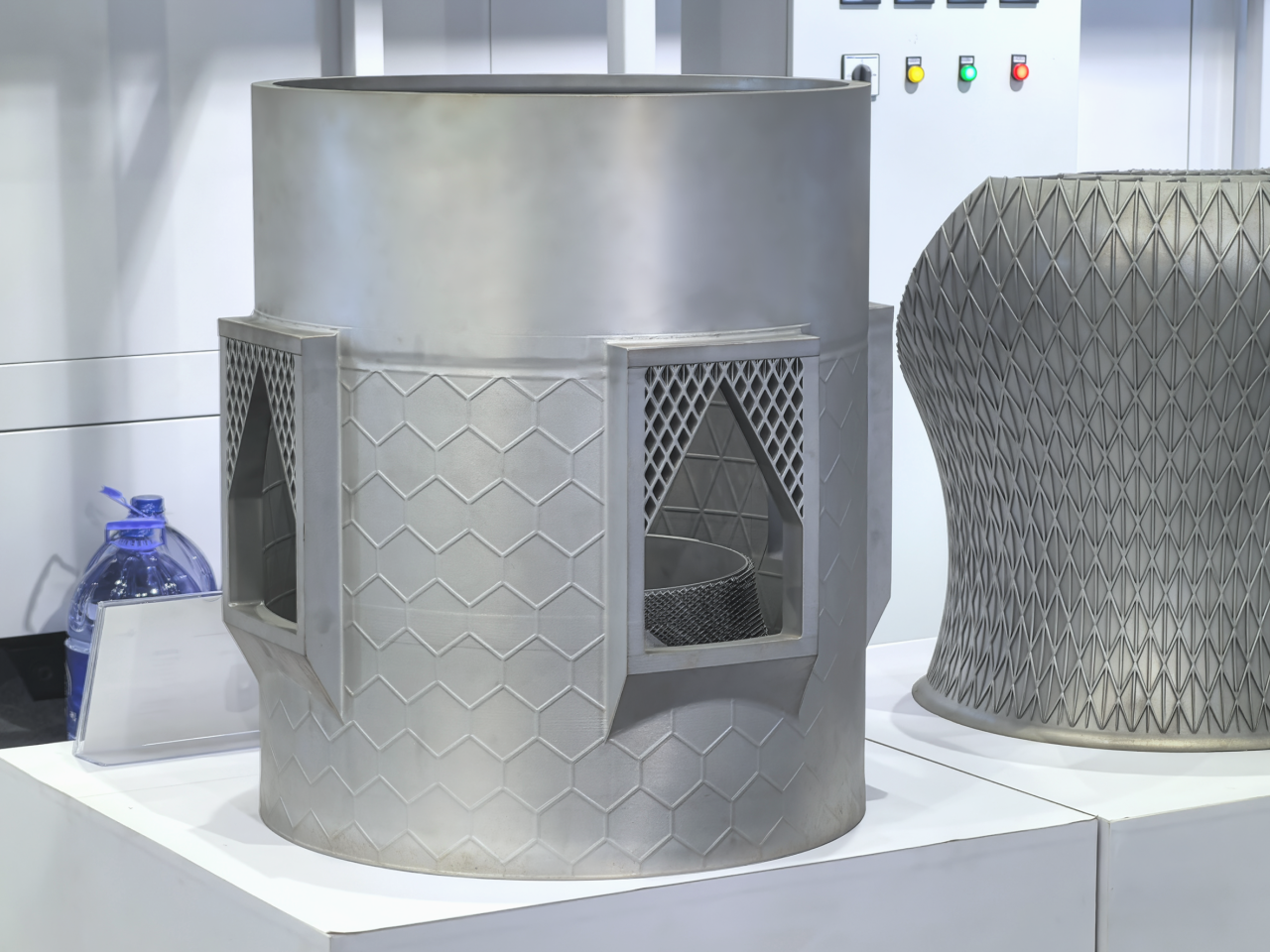

Dozens of typical application cases of metal additive manufacturing were displayed on site, bringing new production ideas to fields such as aerospace and industrial manufacturing.

For the aerospace field, TSC offers an integrated manufacturing solution for complex structural components such as heat exchangers, modules, and flame tube frames. This solution ensures strength while achieving weight reduction and optimization, meeting the strict requirements of the aerospace manufacturing industry for lightweight components and performance accuracy.

In addition, components such as impellers, blades, and thin-walled parts must not only ensure product quality and performance under extreme working environments and complex design requirements, but also achieve processing accuracy requirements at the micrometer level. The turbine guide vane (partial) on display this time adopts a cascade ring structure, which breaks through the limitations of traditional manufacturing processes, simplifies the manufacturing procedures, is integrally formed, enhances the overall performance, and meets the design requirements.

These successful cases not only verify the process performance of TSC Metal 3D printing equipment, but also demonstrate our company's all-round technical support capabilities from the design end to the manufacturing end, which can provide users with full-process solutions from materials, design to manufacturing.

The exhibition will last until October 25th. We sincerely invite you to visit booth C011-6 at Xi 'an Lingkong Convention and Exhibition Center to jointly explore the application prospects of metal additive manufacturing technology in the aerospace field and work together to create a new future for advanced manufacturing.