In the field of manufacturing large and highly challenging metal parts, laser cladding equipment has demonstrated unique value due to its advantages such as high powder utilization rate, intuitive and controllable processing procedures, and continuous and uninterrupted printing. Recently, the LiM-S6010 large-scale customized laser near-net-shape forming equipment of LiM Laser was successfully delivered to an aerospace enterprise in Hubei Province.

Our company has specially developed two core self-researched software for this equipment - LiMAMS-LENS laser near-net-shape forming pretreatment software and LiM-S6010 laser near-net-shape forming monitoring and control system. These precisely address the pain points and difficulties of traditional large-scale additive manufacturing equipment in terms of integration, operational efficiency, and print stability. It provides a solid guarantee for the equipment to print continuously and stably for a long time with high quality.

The intelligent slicing software independently developed by LiM Laser has achieved full-process precise control from model processing to print output, laying a solid foundation for the successful printing of complex parts.

Multi-mode flexible adaptation, precisely responding to process requirements

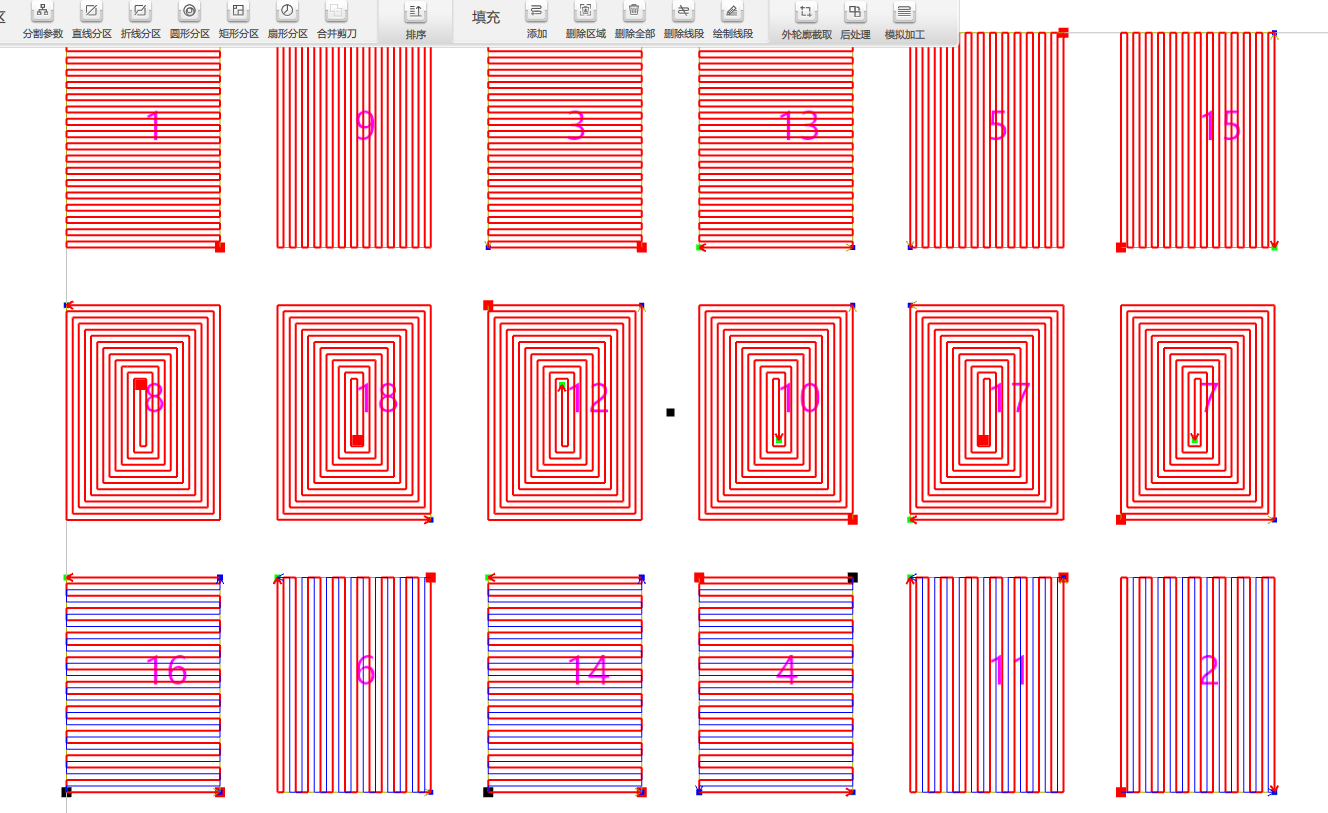

In the preprocessing stage, the self-developed new-generation slicing software demonstrates highly flexible customization capabilities. Supports customizing any layer thickness for slicing, and also allows for planning different scanning paths within the same print layer either automatically or manually. The software offers various filling methods such as bow-shaped lines, parallel lines, spiral lines, and overlapping. Users can freely set the spacing, quantity, starting point, and direction of the filling lines and contours according to their actual needs, precisely matching various printing scenarios ranging from simple to extremely complex.

The self-developed software supports multiple filling methods for the same version and layer slicing

Intelligent partitioning and sorting effectively prevent and control printing risks

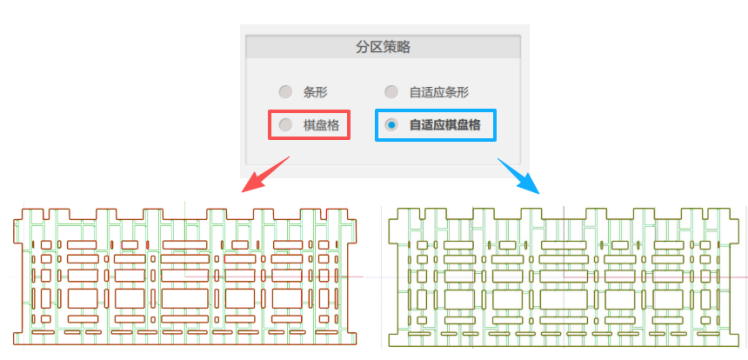

To address the issue of uneven heat dissipation that is prone to occur during the printing of large metal parts, the software integrates adaptive partitioning and intelligent sorting functions. The system automatically completes intelligent zoning based on the geometric shape and hollow structure of the printed parts, ensuring that each zone is relatively independent, which can effectively reduce unnecessary printing interruptions.

Equidistant interlaced chessboard (left)

Adaptive partitioning automatically divides the checkerboard according to the shape of the parts (right)

Relying on advanced algorithms, this software can optimize the printing sequence of each zone according to process requirements, fundamentally avoiding the deformation or cracking problems caused by local heat accumulation due to continuous printing of adjacent zones, and significantly improving the printing success rate.

Based on the self-developed software, the convergence adjustment plate was successfully printed

Parameter synchronization and multi-scheme backup build a solid quality control defense line

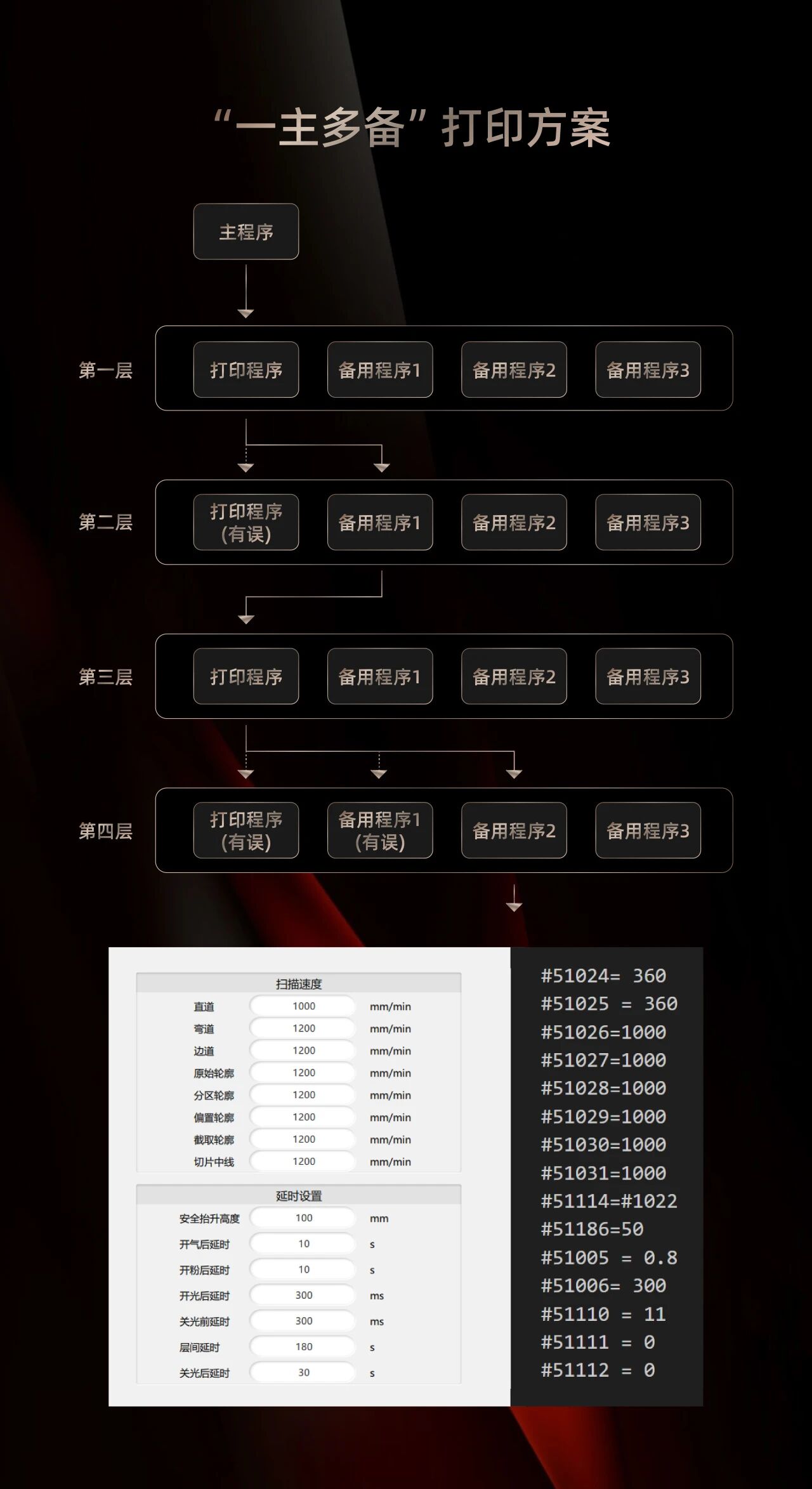

The post-processing stage of the slicing software has achieved a dual upgrade of parameter control and scheme backup. The post-processing parameters set during the slicing process can be directly and synchronously output to the printing program, providing support for the fine control during the printing process and ensuring the precise and consistent execution of the process.

This software supports the configuration of a "one main, multiple backups" printing scheme for each printing layer - that is, in addition to having one main printing program, each layer is also equipped with three or more freely switchable backup schemes. Operators can quickly switch according to the actual situation, greatly enhancing the fault tolerance and continuity of the printing process, and exploring a brand-new security guarantee path for engineering applications.

An example of the "One primary, multiple backups" printing solution

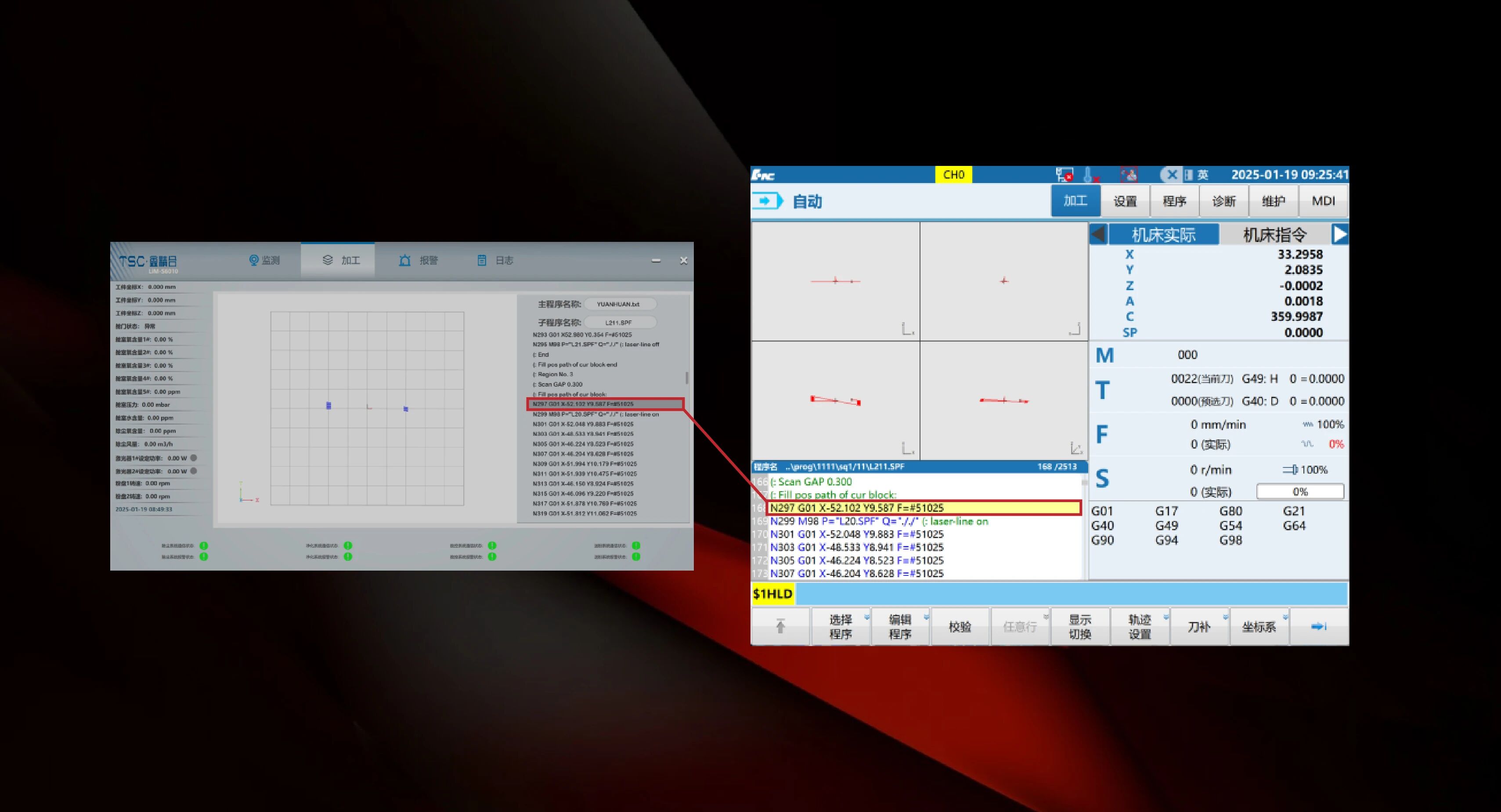

The control software that iterates in coordination with the slicing software constitutes the "intelligent hub" for the stable operation of the equipment, achieving visual and integrated management of the processing process.

Real-time information synchronization and full-process visual monitoring

The control software can centrally monitor key data such as equipment status and process parameters on a single interface, and synchronize relevant information from the slicing software in real time. On the processing monitoring interface, the system synchronously displays the completed processing paths, facilitating operators to intuitively grasp the printing progress, quickly identify and intervene in potential problems, and significantly enhance operational efficiency and process controllability.

Print the ring test piece based on the self-developed software

The independent development of industrial-grade compatible software is an important part of the full-process metal 3D printing solution provided by LiM Laser. This time, the intelligent slicing software and control system tailored for the LiM-S6010 equipment not only significantly enhanced the equipment's efficiency and the standardization level of the process, but also demonstrated the company's comprehensive strength in software development.

In the future, LiM Laser will continue to delve deeply into various types of metal 3D printing technologies, further improve its independent software ecosystem, and with more intelligent and stable digital solutions, assist in upgrading manufacturing capabilities in the aerospace field, contributing innovative power to China's intelligent manufacturing.