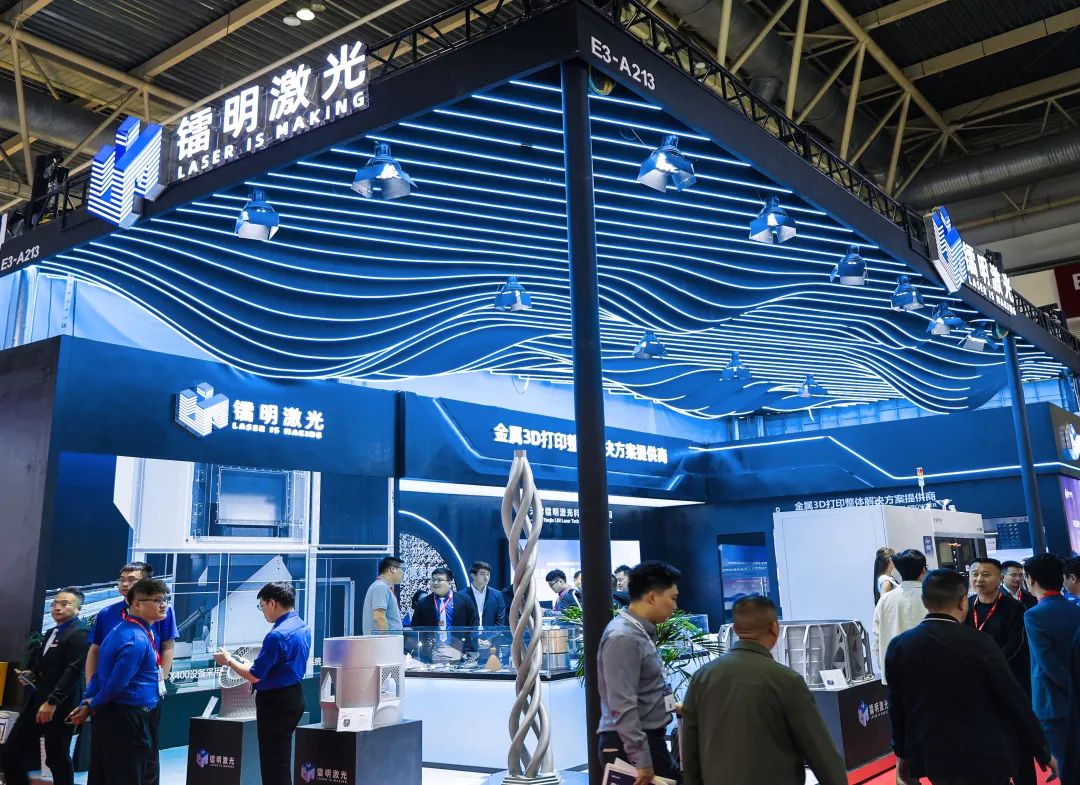

On April 26th, the 19th China International Machine Tool Exhibition (CIMT 2025) came to an end. As a "barometer" of the global manufacturing industry, the exhibition gathered advanced technologies and innovative achievements from around the world. LiM Laser, as an advanced enterprise in the metal 3D printing industry, brought cutting-edge metal additive manufacturing solutions to this exhibition. With the "additive thinking" approach to solving processing difficulties, and with its forward-looking technological layout and rich application cases, it has attracted the attention of many professional visitors from home and abroad.

Subverting Traditional Manufacturing and Driving Industry Change

LiM Laser LiM-X400M+ equipment on-site real-time printing, to help the audience understand the working principle of metal 3D printing, fully demonstrated the unique advantages of additive manufacturing.

LiM-X400M+ equipment has a molding size of 400mm×300mm×450mm (W×D×H), relying on 3×500W laser for efficient molding, with functions such as grafting printing, variable layer thickness printing, substrate temperature control, etc., which has obvious advantages in solving the pain points of production in the fields of mold manufacturing, 3C electronics, and so on.

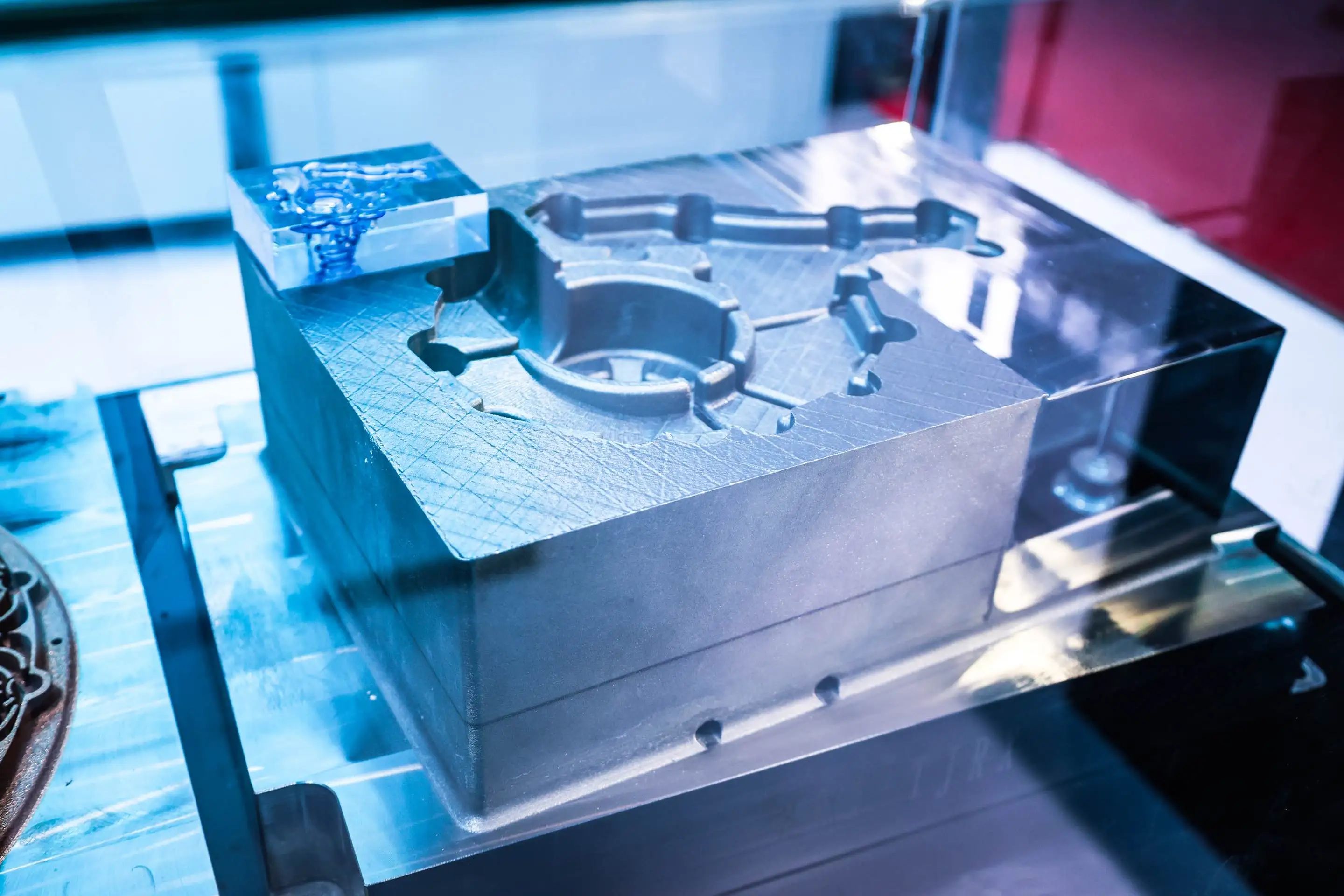

Waterway Mold

Exhibit size: 343mm×242mm×120mm

Printing device: LiM-X400M+

Printing time: 120h

The mold is used in the manufacture of automotive parts, the interior has complex and rich with the shape of the cooling waterway, the use of SLM molding, shorten the mold processing time, reduce the difficulty of processing, so that the production and processing process is more green and environmentally friendly.

Grafted waterway mold

Exhibit size: 114mm×122mm×160mm

Printing equipment: LiM-X260A

Printing time: 60h

The mold adopts the manufacturing method of “machining + 3D printing”, in which the cutting plane of the traditional machined parts is used to individually form the cooling part of the mold inserts, which not only reduces the production cost, but also helps to shorten the production cycle.

Drone frame

Exhibit size: 153mm x 153mm x 25mm

Printing device: LiM-X260A

Printing duration: 5h

Adopting topology-optimized structural design scheme reduces the number of parts and shortens the manufacturing process and production cycle; one-piece molding effectively safeguards the mechanical properties, reduces the quality risk, and significantly improves the overall reliability of small and complex parts.

Bulk cell phone hinge

Exhibit size: 262mm×262mm×189mm

Printing equipment: LiM-X260A

Printing time: 116h

This case fully embodies the mass production application of SLM technology in the 3C electronics field. Full-page printing and large-scale mass production can effectively reduce production costs. The use of titanium alloy material in the hinge, a key part of folding screen cell phone, weighs only 132g and can be folded more than 400,000 times, significantly improving the service life of folding screen cell phone.

In addition, LiM Laser also exhibited a variety of large-sized and complex structural parts in the aerospace field, comprehensively demonstrating the level of process technology.

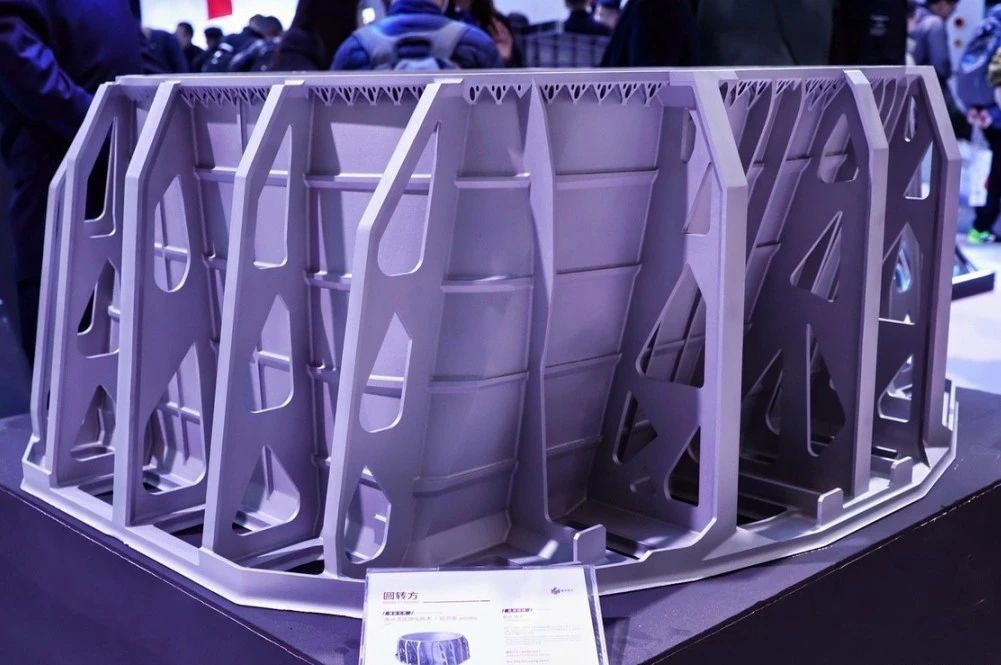

Round to Square

Exhibit size: 1290mm×1180mm×506mm

Printing equipment: LiM-X1500H

Printing time: 288h

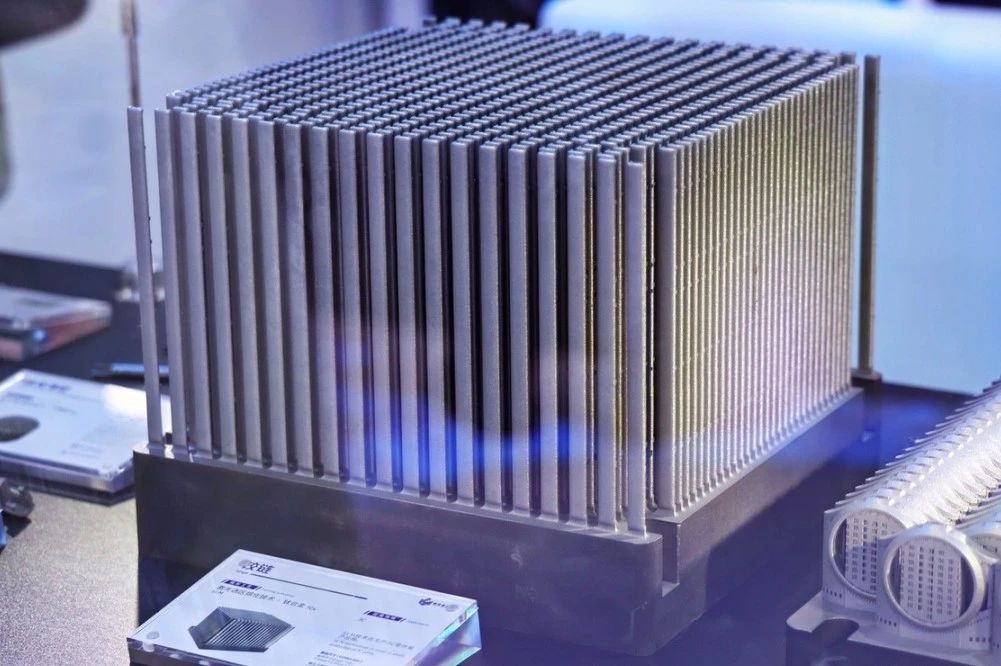

Heat exchanger

Exhibit size: 569mm×527mm×512mm

Printing device: LiM-X650

Printing time: 192h

Spiral structural parts

Exhibit size: 418mm×362mm×2210mm

Printing device: LiM-X800H+

Printing time: 305h

Continuously plowing into the industry to drive manufacturing change

LiM Laser continues to plough into the metal 3D printing industry, adhering to the concept of “making manufacturing more efficient”, constantly breaking through technical bottlenecks, helping more large-sized and complex structural parts to be formed in one piece, and at the same time providing better solutions for the batch manufacturing of small and medium-sized parts.

Based on LiM-X series SLM equipments, LiM-X provides customized solutions covering the whole life cycle of metal 3D printing for users in various fields, which can realize cost reduction, efficiency and high quality production, no matter it is a precision part or a super-large complex structural part. For printing quality control, SiM-XLM has developed systems such as melt pool monitoring and powder bed monitoring to ensure stable and reliable molding quality of parts.