TSC metal additive solution, help the country's heavy instrument to pursue the dream sky

On November 12, the 15-day Airshow China opened in Zhuhai, Guangdong Province, with TSC's overall metal 3D printing solutions and innovative achievements.

Aerospace is a strategic field to promote national defense construction, scientific and technological innovation and economic and social development, and has a strong role in improving the upstream and downstream industrial systems, and promoting the construction, extension, reinforcement and strengthening of the industrial chain. Metal 3D printing, as one of the innovative technologies of industrial machines, has been deeply applied in the aerospace manufacturing industry.

Aerospace products are mostly required to serve under extreme conditions, showing a high degree of integration and integration characteristics: a wide variety of components and interconnections, emphasizing the overall coordination; Material selection, processing accuracy, performance requirements are different; Highlighting large-scale, lightweight, etc., which also causes aerospace parts design difficulty, high manufacturing costs, long production cycle, and slow iteration speed. However, the popularity of metal 3D printing technology eliminates the need for open mold manufacturing, directly forms large-size, high-precision, high-performance key parts, shortens the trial-production verification cycle, accelerates the research and development process, and further promotes the development of advanced manufacturing technology in the field of space. TSC is deeply engaged in metal 3D printing technology and integrates practical experience to provide overall metal 3D printing solutions for high-end manufacturing industries represented by aerospace, so as to achieve mass production quickly and efficiently.

Large size complex structural parts manufacturing

Taking the cascade ring as an example, the diameter of the key component in the aerospace engine is 1470mm, the whole is a compound impeller structure, the number of blades is large and thin, and the processing is difficult. Using laser selective melting technology, the large size complex parts are formed in one body, the finished product surface is dense without defects, the connection structure has no solder joints, the whole is uniform, and the performance is excellent. The material is superalloy (GH3625) to ensure its normal operation in high temperature, high pressure and high speed air flow. The outer surface is covered with reinforcing bars to increase the mechanical properties of the structure such as strength and stiffness. Using LiM-X1500HF flight printing equipment, 20 laser prints were manufactured in 240h, demonstrating high quality and efficient production capabilities for large size aerospace components.

Cascade ring

The thrust chamber, an important component of space engines, uses laser selective melting technology to achieve lightweight design and reduce weight to 600kg. The diameter of the part is 589mm, the overall height is 1357mm, and it only takes 360h to print; Integrated shape, the internal flow path structure design is more free, manufacturing more accurate; No solder joints on the surface, high finish, reliable strength; External texture fit application requirements, high process stability. This part fully demonstrates the experience and ability in the forming of large sizes, especially ultra-high size complex parts.

Thrust chamber

Multi-process, multi-material combination manufacturing

In practical applications, special parts in the aerospace field often need to be coupled by a variety of materials, and the process and performance requirements are also different. In response to such needs, the subsidiary LiM Laser uses multi-alloy, multi-process combination 3D printing to manufacture parts, which not only shortens the production cycle and processing costs, but also ensures the quality and performance of the finished product.

Taking the aero engine thrust chamber as an example, the part has many fine structures, complex internal flow channels and thin wall structure. First, the laser selective melting technology is used to complete the integrated forming of copper alloy (CuCrZr), and then the superalloy (GH4169) cladding layer is added to the external surface by laser cladding technology to achieve the purpose of surface modification. The final product combines high thermal conductivity and high strength.

Thrust chamber

A certain type of front fuselage product has complex overall structure, large size, high precision requirements, many key positions, and difficult processing. In actual manufacturing, LiM Laser fabricated and connected the entire fuselage into three section structures and two frame and beam structures. The six-stage piecewise forming method is adopted to control the deformation effectively after each stage is completed. Web beam parts are manufactured by web + laser deposition to optimize the forming scanning strategy, reduce the unit heat input, and increase the chamfer in the area with large cross-section changes to reduce stress concentration and ensure the forming quality.

Front middle body product of a certain model

Precision structure high quality forming

Aerospace products put forward strict requirements for precision, especially impeller, blade, thin-wall structure and other parts, to ensure product quality and performance in extreme working environments and complex design requirements, but also to achieve micron-level processing accuracy requirements.

The main structure of a satellite printed by TSC is made of aluminum alloy. In order to overcome the problem of deformation and cracking of large plane and large size, a typical thin-wall sandwich structure design is adopted: the combination of thin-wall panel + lattice inner core can not only realize the rapid lightweight of components, but also has the advantages of high strength, good plasticity, fatigue resistance, sound absorption and heat insulation. Relying on metal 3D printing, thin-walled sandwich structural parts can be formed in one body, the internal lattice structure is intact, uniform thickness, accurate and reliable.

Main structure of a satellite

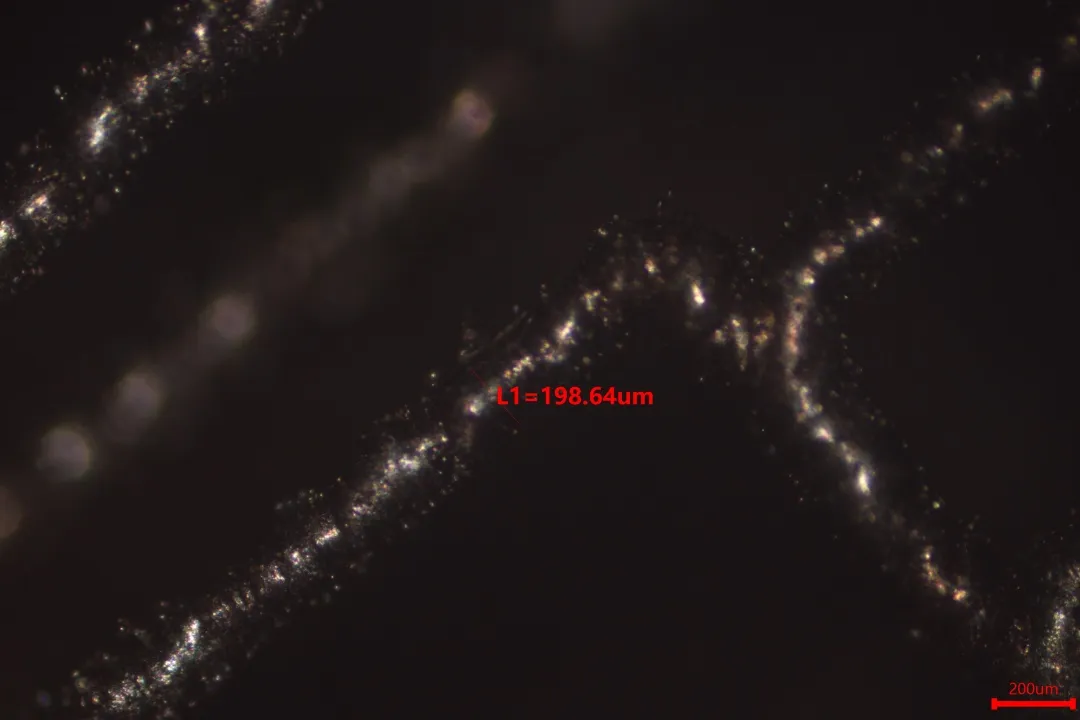

Printed large area (150mm×150mm) limit size structural parts, the material is aluminum alloy, the overall structure of the formed parts is intact, the rod diameter is only 0.2mm, the dimensional accuracy is ±0.025mm.

Magnify the partial rod diameter diagram by 50x

The printed product can meet the forging performance requirements

The requirements for structural design of aerospace parts are getting higher and higher, and the requirements for forming quality of parts are more stringent.

The tail nozzle, an important part of the turbojet engine, has an envelope size of 500mm×870mm×2880mm, multiple internal flow channels, and difficult deformation control of the rotary body. It is manufactured by laser selective melting + material reduction forming, which takes 720h to make, and the final product meets the performance requirements of the forging.

Tail nozzle

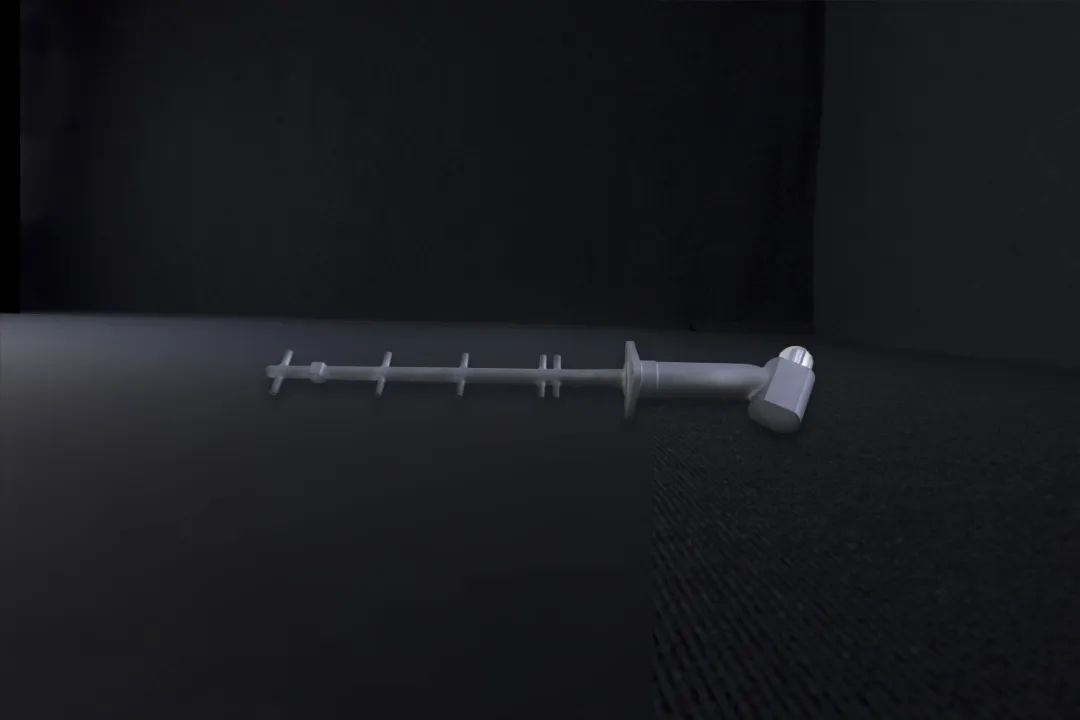

Printed a certain type of jet fuel injection rod, the use of metal 3D printing integrated forming, instead of the original welding splicing scheme, and ultimately reduce the number of welds 14, greatly improving the stability of product quality.

Jet fuel injection rod

The self-developed metal 3D printing equipment of the subsidiary LiM Laser has been tested by users for a long time, stable and reliable operation, providing strong support for the high-quality and efficient mass production of spare parts in the space field, and participating in national engineering projects for many times. In the new generation manned spacecraft test ship project, LiM-S2510 laser near-net forming equipment was used to print the heat-proof outsole frame of the return capsule with a diameter of 3.95m, which solved the problem of "deformation and cracking" of large integral components, and achieved outstanding results in improving manufacturing accuracy, increasing manufacturing size and improving production efficiency. The material utilization rate is increased by 67%, which greatly improves the subsequent assembly efficiency.

Heat-proof outsole frame of reentry capsule

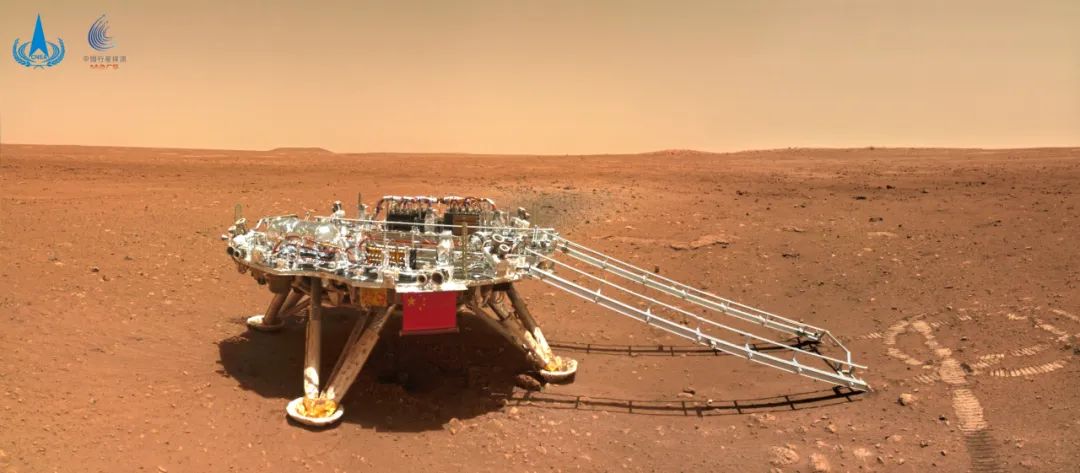

In 2021, the "Tianwen 1" probe will land on Mars, taking an important step in China's journey of interstellar exploration. In the process of task development, more than 30 products of LiM-X series laser selective melting equipment were manufactured and delivered, and 9 products of LiM-S series laser near-net forming equipment were manufactured and delivered.

Sky Man 1 probe

In recent years, the global aerospace industry has been booming, from engine components to satellite components, and then to aircraft structural parts, the application of 3D printing is changing the production mode of aerospace manufacturing; In addition, the steady development of low-altitude economy and commercial space track has also accelerated the development and improvement of metal 3D printing technology, which has become the normal manufacturing means of parts research and development and trial production and mass production. As a pioneer in the metal 3D printing industry, TSC has always been guided by user needs, optimizing equipment stability, strengthening process technology development, upgrading service quality, strengthening market competitiveness, and providing diversified metal 3D printing overall solutions for users in the aerospace field.