From November 21st to November 23rd , the development of aerospace and navigation industry sponsored by Hunan Provincial State-owned Assets Supervision and Administration Commission, Hunan Provincial Department of Industry and Information Technology, Hunan Provincial Department of Commerce, Changsha Municipal People's Government, China Ship Information Center and China Aviation Research Institute The forum was held in Changsha, Hunan. The theme of this year's forum is " New Technology, New Ecology, and New Three Airlines " . Authoritative experts, relevant leaders, and industry elites in the industry all attended to participate in a high-quality event in the fields of aerospace, aviation, and navigation.

Focus / three aviation industry

TSC & LiM Laser's innovative achievements were on display

At the same time as the forum , special exhibitions on scientific and technological innovation achievements, excellent technical equipment and product supporting solutions in related industries of " three airlines " were held. As a first-class enterprise in the field of metal additive manufacturing, TSC & LiM Laser will exhibit and display metal 3D printing equipment, metal 3D printing results and application research and development results in the fields of aerospace, aviation and navigation.

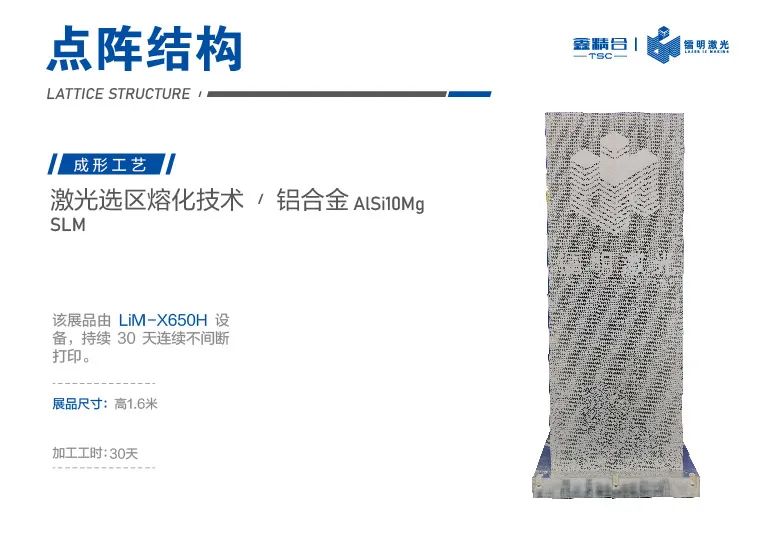

Using the LiM-X650H equipment to print continuously for 30 days without interruption, the 1.6 - meter-high dot matrix structure can effectively meet the requirements of lightweight structure. The forming size of the equipment is 650mm×650mm×1680mm . It adopts the self-developed patented gantry double drive structure, which can reduce the overall height of the equipment while realizing the printing height. It is widely used in aerospace, aviation, navigation and other fields.

At the same time, we shared a variety of metal 3D printing equipment independently developed by TSC & LiM Laser , focusing on the LiM-X800 equipment released not long ago. As a large-scale additive manufacturing equipment, it supports ten laser printing and has a larger forming size. , It can better meet the needs of spaceflight, aviation and navigation.

The booth attracted many guests to stop and watch the exhibition by virtue of cutting-edge technological innovation. TSC & LiM Laser conducted in-depth docking and communication with professionals in various industries, and looked forward to future exchanges and cooperation.

Deep cultivation / Technology research and development

Facilitate large-scale production of additive manufacturing industry

Relying on the technology accumulation and industry exploration in the field of metal additive manufacturing for many years, TSC & LiM Laser has undertaken a large number of additive manufacturing technology research tasks in the fields of aviation, aerospace, aviation development, shipbuilding, energy and medical treatment, and has Batch machine application has been realized.

In the future, TSC & LiM Laser will continue to strengthen technical reserves, deepen technology research and development, continue to iterate on the research and development of metal additive manufacturing equipment, further improve the stability and reliability of equipment, and help the large-scale production of China's additive manufacturing industry.

Understand / market demand

Provide high-quality solutions for metal additive manufacturing

In this forum, TSC & LiM Laser met many potential partners. Through in-depth discussions and exchanges, the market demand will become clearer, and together with industry colleagues, we will use new technologies to build a new ecology of the aerospace and navigation industry, and contribute to the development of the new three aviation industries.

In the future, TSC & LiM Laser will continue to adhere to high-quality manufacturing, be user-oriented, focus on product innovation and development; closely follow the development trend of the additive manufacturing industry, and provide users with high-quality metal additive manufacturing solutions.