3D printing has the characteristics of personalization and high precision. After effective combination with digital medical technology, it can easily realize the large-scale customization of personalized medical products, and profoundly change the concept, method and pattern of the medical industry.

1. Widely used in the customization of pathological models, surgical guides, prosthetics, skull repair, dentures, implants and other medical instruments

2, can use titanium alloy, cobalt-chrome-molybdenum alloy and other metal materials to meet the requirements of biocompatibility

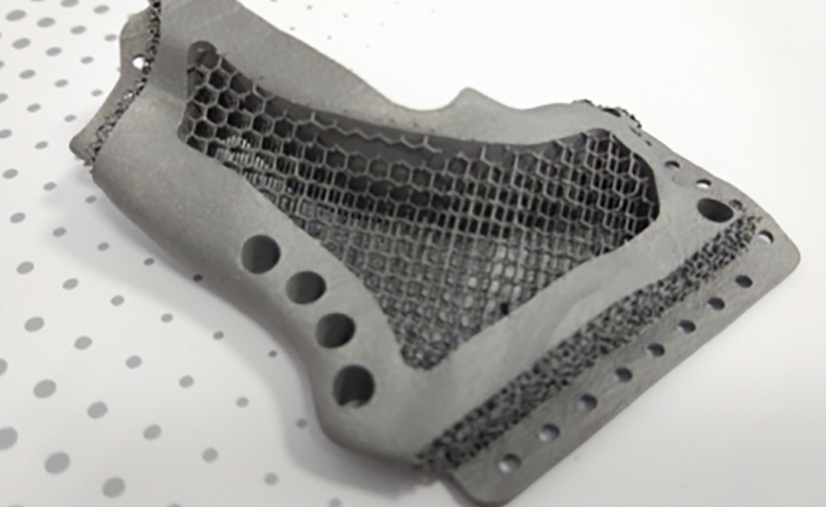

3. Metal 3D printed implants with honeycomb structure

The complex honeycomb structure based on finite element analysis can meet the biomechanical requirements of human body, effectively extend the service life of the implant, facilitate the rapid fusion and growth of muscle, blood vessel and bone tissue with the implant, and greatly shorten the postoperative healing time

4. 3D printed metal crowns and implants

Based on the oral scanning technology, the direct digital manufacturing of denture can be realized, the processing cycle can be shortened, and the mass customization of personalized products can be realized

The maxillofacial bone and femoral stalk of orthopedic implants are lightweight design, which can reduce the weight by more than 50%, and the strength fully meets the design requirements.